AIQIHHON SMART TECHNOLOGY

With the application and promotion of intelligent manufacturing, more and more manufacturing companies have begun to value the value of industrial robots. Efficient and innovative production mode can meet the needs of enterprise modernization development. Industrial robot is widely used in the fields of palletizing, assembly, sorting, painting, spraying, picking, packaging, press connection, die casting, loading and unloading, polishing, etc., which can bring great convenience to the production of enterprises.

The intelligent handling system is based on an industrial robot. Handling robot uses full servo drive, positioning and precise motion trajectory, fast response speed, safe and reliable performance. In addition, the robot itself has a light weight and a small footprint, and can complete tasks independently, or it can be combined with other equipment or robots to form a system. Industrial robots are driven by 4 or 6 axis servos, and their payload ranges from 6KG to 1300KG. The robot can grab single cardboard boxes or plastic boxes, as well as groups of goods. The cargo holding device can be individually designed according to the actual situation.

Spraying is a very important process, and has very high technical requirements. Spraying robot have improved coating efficiency and saved paint. Compared with the traditional air spray gun, the automatic spraying robot uses electrostatic spraying. The centrifugal force generated by the high-speed spray cup can make the coating atomize well. Even in thick spraying places, a good coating film can be obtained.

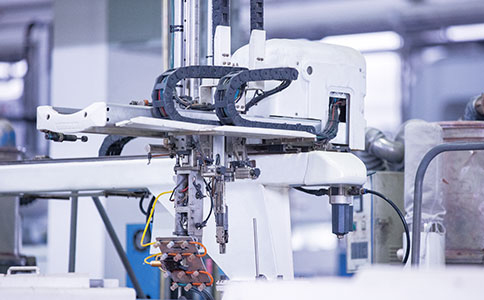

Repetitive and monotonous and requiring smooth insert operations, which poses a certain challenge to the stability of manual operations. While guaranteeing the accuracy and stability of the inserts, Embedded robot can continuously run and avoid possible problems in manual operations such as decision errors and inaccurate information determination. The characteristics of the robot have won a higher level for injection molding. Production efficiency and guaranteed reliable cycle time effectively improve the equipment performance of the injection molding system itself.

The welding robot has a short response time and fast action. The welding speed is 60-3000px / minute, which is much faster than manual welding, which improves production efficiency. When welding with a robot, the welding parameters for each weld are constant. The quality is less affected by human factors, which reduces the requirements for workers' operating techniques, so the welding quality is stable

Address:

NO.105,building 8,China mould expo city,Huangyan,Taizhou,zhejiang

Tel:0576-89182555

Phone:13957616338

Phone:13456662900

E-mail:qihongzhineng@126.com

Copyright © 2019 AIQIHHON smart technology All rights reserved.